Flinks: https://www.pinsimotion.com

Date:2023-10-14 09:07:01

Linear motion systems are essential components in various industries, enabling precise and smooth movement in machinery and equipment. However, they can encounter certain challenges that affect their performance and efficiency. This article will discuss some common challenges faced in linear motion systems and provide valuable tips and solutions to overcome them. At PINSI, we understand these challenges and offer high-quality linear guides, ball screws, and cross-roller guides to help you optimize your motion systems and achieve seamless operation.

1. Lack of Precision and Accuracy:

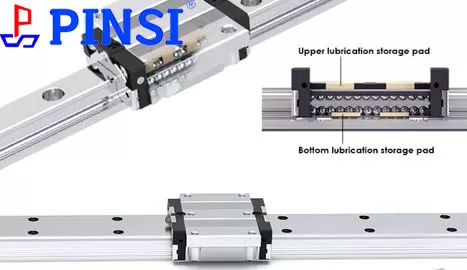

One of the primary challenges in linear motion systems is maintaining precision and accuracy over time. Factors such as wear, misalignment, and inadequate lubrication can lead to deviations and compromise the performance of the system. To address this, regular maintenance is crucial. Ensure proper lubrication of the linear guides and ball screws, inspect for any signs of wear or misalignment, and make necessary adjustments or replacements. Investing in high-quality components from PINSI guarantees superior precision and accuracy in your motion systems.

2. Excessive Friction and Noise:

Friction and noise are common issues that can arise in linear motion systems, hindering their smooth operation. This can be caused by various factors, including improper lubrication, contamination, or misalignment. To minimize friction and noise, ensure proper lubrication with high-quality lubricants recommended by the manufacturer. Regularly clean and remove any debris or contaminants from the linear guides and ball screws. Additionally, opt for precision-engineered components, such as PINSI's linear guides and ball screws, which are designed to reduce friction and noise for optimal performance.

3. Insufficient Load Capacity:

Linear motion systems often need to handle different loads and forces. Insufficient load capacity can lead to premature wear, reduced accuracy, and potential system failure. It is crucial to select linear guides, ball screws, and cross roller guides with adequate load capacity for your specific application requirements. PINSI offers a wide range of products with various load capacities to suit different applications, ensuring reliable and efficient operation even under heavy loads.

4. Environmental Factors and Contamination:

Harsh environments and contamination pose significant challenges to linear motion systems. Dust, debris, moisture, and corrosive substances can impact the performance and lifespan of the components. To combat these challenges, consider implementing protective measures such as sealing options, bellows, or covers to shield the linear guides and ball screws from contaminants. PINSI's products are designed with robust sealing options and surface treatments, ensuring enhanced protection against environmental factors and contamination.

5. Inadequate System Integration:

Proper system integration is vital for optimal performance of linear motion systems. Ensure that the linear guides, ball screws, and cross roller guides are compatible with other system components and correctly aligned. Proper installation and alignment will help maximize system efficiency, minimize wear, and prevent premature failures. If you require assistance with system integration or component selection, PINSI's technical experts can provide guidance and support to ensure seamless integration and improved overall performance.

Conclusion:

Overcoming common challenges in linear motion systems is essential to maintain their performance, precision, and efficiency. By addressing issues such as lack of precision, excessive friction, insufficient load capacity, environmental factors, and inadequate system integration, you can optimize the operation of your motion systems. PINSI's high-quality linear guides, ball screws, and cross roller guides offer reliable solutions to these challenges, ensuring smooth and reliable linear motion in your machinery and equipment. Visit our website to explore our comprehensive range of products and experience the difference in your linear motion systems.